How AI is Transforming the Manufacturing Sector

Artificial Intelligence AI is transforming the manufacturing sector and empowering to grow their business productivity, reduce costs, and improve quality. AI has affected nearly every part of the manufacturing process from predictive maintenance to quality inspection, and beyond.

Preventive Maintenance: No More Downtime

Predicting the Future Breakdowns of equipment can lead to expensive downtime and loss in production settings. Machine-learning-based predictive maintenance uses AI to analyze sensor data from machines and predict failure. Businesses can repair or replace the equipment just in time.

- How it works: AI algorithms track parameters such as temperature, vibration, or pressure continuously to identify variations in real-time data.

- Pros: Decreased unplanned downtime, longer life of machinery, and reduced repair costs.

- Example: An AI system monitors conveyor belts in a factory. The belt will be ready for repair before it fails, preventing a production delay.

AI is Transforming the Manufacturing Sector: quality checks and error detection.

AI vision systems are revolutionizing quality control, enabling production line defects to be detected by computers more quickly. This will guarantee that you catch all problematic items before they reach the customer. That will in return limit waste and improve customer satisfaction.

- How It Works: AI cameras analyze items in real time and discover defects that may not be detectable by the human eye.

- Pros: Uniform quality, low incidence of recalls, and reduced material reject rate.

- Example: An automotive parts manufacturer employs AI-based inspection systems to identify minuscule cracks in metal components, thus guaranteeing only the best quality parts make their way out of production.

Supply Chain Optimization

The use of AI also makes the supply chain more efficient when it comes to predicting demand, having stock in line with that, and putting out logistics. By using machine learning and other AI-driven predictive analytics, demand forecasting solutions are analyzing voluminous historical data collected through the years to derive insightful predictions on future trends of changing demands coupled with impact from potentially millions of varying forces including competitors’ behavior all around.

- How it works: AI systems will predict what materials or products are going to be needed and suggest how much of an inventory should be kept.

- Pros: Lower overstock and shortages, better production planning, higher sales satisfaction with retailers.

- Example: An AI solution predicts order volumes for different foods (preventing package dry goods shelf-life expiration) so that a food manufacturer stocks the ideal ingredients.

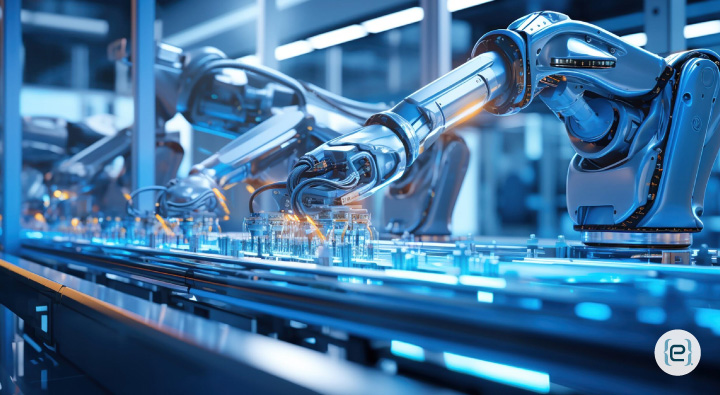

AI is Transforming the Manufacturing Sector: robotics and Automation

AI powers smart robots, or these automated systems are designed to repeat the same tasks with great accuracy. Cobots (or collaborative robots) operate alongside humans to increase efficiency and reduce human hazards.

- How it works: Robotic assembly, packaging, and material handling perform quicker than before with the help of AI algorithms.

- Pros: Speed production Improved employee safety Reduced operation costs

- Example: A manufacturer of electronic components uses robots with AI to put together circuit boards as error-free and productivity gains.

Sustainability in Energy Management

This even includes AI use in lowering energy usage and increasing the sustainability of manufacturing plants. An AI-driven energy management system will also track how you use your power, and then suggest ways in which consumption can be better time managed to reduce cost without compromising the productivity output.

- How it Works: Artificial Intelligence algorithms parse the data for energy and detect any wasteful use of it.

- Pros: Lower energy costs, reduced carbon footprint, and aids in sustainability goals.

- Example: In a factory, AI can be used to control the HVAC systems as well as lighting and machinery so that they operate at an optimum setting during non-peak hours thereby conserving energy.

AI is Transforming the Manufacturing Sector: Digitizing the production and going further with digital twins

Simply put, a digital twin (DT) is the virtual representation of a product or manufacturing process that allows you to run simulations and optimize operations. AI-driven digital twins offer immediate feedback and give manufacturers the ability to model various scenarios without having to do anything in the physical world.

- How It Works: AI uses data from sensors to build a digital lamp of the production process, giving it the ability to simulate and analyze.

- Pros: Faster production OR Less Production errors Better efficiency.

- For example: a factory can leverage a digital twin to simulate changes on the production line (instead of actual modifications that will halt regular operation for prolonged periods).

Enhanced Worker Safety

AI is transforming the manufacturing sector and tracks worker activity and spots potential workplace dangers. AI wearable devices can send real-time alerts to workers and supervisorswhich might reduce accidents.

- How it works: AI uses data from wearable sensors and surveillance cameras to identify unsafe behaviors or hazardous conditions

- Pros: Reduction in workplace injuries, fewer safety violation fines

- Use case: An industrial chemical company employs smart wearables equipped with AI software to track exposure levels of workers who may meet harmful gases, triggering warnings when those exposures cross a threshold ganglion.

Recent Posts

Align, discuss, achieve

The Importance of Internal Meetings for Continuous Improvement Internal meetings are a crucial part of…

Cloud Townships: Smart, Connected Cities of Tomorrow

Discover how cloud townships are revolutionizing urban living with smart infrastructure and IoT, enhancing sustainability…

Business Continuity Planning: A Key to Maintaining Resiliency, Avoiding Downtime

In a world that is evolving more rapidly than ever before, and considering globalization where…

How BrightGauge Turned Reporting and Dashboards into Business Insights

Data is the lifeblood of modern business, and the ability to properly analyze that data…

Boosting Business Efficiency with Microsoft 365

Boost Productivity and Collaboration with Microsoft 365 Efficiency has to be job number one for…

Azure VPN Gateway

The Need for Secure Remote Connectivity in Modern Business In today’s digital-first world, businesses need…